Your Reliable Solar Mounting Aluminum Profiles Manufacturers

Our Solar Mounting Aluminum Profiles are designed to deliver reliable performance, clean aesthetics, and flexible integration for a wide range of applications. Manufactured from high-grade aluminum and processed with precision extrusion techniques, these profiles offer a balanced combination of strength, lightweight structure, and durability. With customizable specifications and consistent production standards, we help customers efficiently adapt these profiles to their specific project requirements, from small-scale customization to bulk manufacturing needs.

Request A QuoteProduct Categories

Solar Mounting Aluminum Profiles

Solar Mounting Aluminum Profiles are engineered structural components used to support and secure photovoltaic systems in various installation environments. Manufactured from high-strength aluminum alloys, these profiles are valued for their lightweight structure, corrosion resistance, and long-term outdoor durability, making them ideal for solar applications exposed to changing weather conditions. Designed with functional cross-sections and precise tolerances, our solar mounting profiles ensure stable panel alignment, efficient load distribution, and easy on-site assembly. They are widely applied in rooftop systems, ground-mounted arrays, and solar carports, supporting both residential and commercial solar projects. installations.

Technical Features And Advantages

We are committed to providing the highest quality solutions, with comprehensive support and innovative technologies.

High Structural Strength

Designed to support solar panels securely under wind and load conditions.

Excellent Corrosion Resistance

Aluminum alloy ensures long-term durability in outdoor environments.

Lightweight Construction

Reduces overall system weight while maintaining reliable load capacity.

Installation Flexibility

Supports different mounting systems with adjustable and modular designs.

Main Products

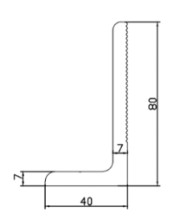

L Feet

Solar Mounting Aluminum Profiles

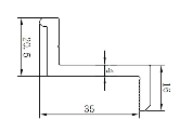

L Feet are L-shaped aluminum mounting components designed for photovoltaic installation systems. The right-angle structure provides stable support between solar rails and mounting surfaces, allowing precise alignment and secure fixation. Its compact shape fits well in rooftop and ground-mounted solar structures, helping distribute loads evenly and maintain structural balance. The slotted hole design allows installation adjustment during assembly, improving adaptability to different roof conditions and project layouts.

Solar Panel Clamps

Solar Mounting Aluminum Profiles

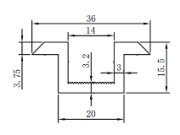

Solar Panel Clamps are aluminum mounting components designed for side clamping of photovoltaic modules. The clamp structure applies lateral pressure to securely fix solar panels onto mounting rails while maintaining accurate alignment. Its compact profile allows installation at the edge of panels, making it suitable for framed photovoltaic modules in rooftop and ground-mounted systems. The clamping shape is engineered to distribute force evenly, helping reduce stress on the panel frame during installation and long-term use.

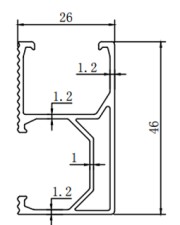

Solar Panel Mounting Rails

Solar Mounting Aluminum Profiles

Solar Panel Mounting Rails are structural aluminum guide rails designed for photovoltaic mounting systems. As the main load-bearing component, the rail provides a continuous and stable mounting base for solar panels, clamps, and other fixing accessories. Its linear cross-section is engineered to support precise alignment and efficient load distribution, helping ensure the correct orientation and spacing of photovoltaic modules. The rail shape allows compatible clamps and connectors to slide or lock into position, enabling flexible system assembly.

Aluminium Solar Panel Mounting Rails

Solar Mounting Aluminum Profiles

Aluminium Solar Panel Mounting Rails are structural guide rails designed for photovoltaic mounting systems, providing a stable and reliable base for fixing solar panels and related accessories. Manufactured from high-strength aluminum alloy, the rails offer good corrosion resistance and durability for long-term outdoor use. The extruded rail profile allows clamps and connectors to be securely positioned along the length, supporting flexible system layout and precise alignment. Dimensions, cross-section designs, and surface treatments can be customized to meet different project requirements, making the rails suitable for rooftop, ground-mounted, and large-scale solar installations.

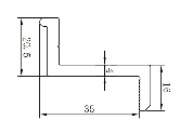

Solar Panel End Clamps

Solar Mounting Aluminum Profiles

Solar Panel End Clamps are fastening components used in photovoltaic mounting systems to secure solar panels at the outer edges of the array. Installed at the beginning and end of mounting rails, the clamps apply controlled pressure to hold the panel frames firmly in place, ensuring stability and proper alignment. They work together with rails and other mounting accessories to prevent panel movement caused by wind or vibration. Manufactured from aluminum alloy, end clamps are suitable for long-term outdoor use and play a key role in maintaining the overall structural integrity of solar panel installations.

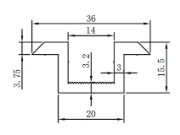

Solar Panel Mid Clamp

Solar Mounting Aluminum Profiles

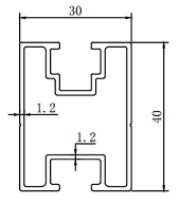

Solar Panel Mid Clamp is a key fastening component used in photovoltaic mounting systems to secure adjacent solar panels along the mounting rails. Installed between two panels, it applies balanced lateral pressure to hold modules firmly in place while maintaining consistent spacing. Manufactured from high-strength aluminum alloy with surface treatment, mid clamps ensure reliable structural stability under wind and snow loads. Their standardized design allows quick installation, compatibility with different panel thicknesses, and long-term performance in outdoor environments, making them an essential part of efficient and safe PV installations.

Integrated Solution

Integrated Solution 1

This integrated solution for Solar Mounting Aluminum Profiles includes mounting rails, clamps, connectors, fasteners, and related accessories designed to work as a complete system. All components are engineered for compatibility, structural stability, and efficient installation, supporting reliable solar panel fixation across different installation environments.

| PRODUCTS | SPECIFICATION | MATERIALS | QTY. (PCS) |

| Rail | 2500mm | Aluminum Alloy | 20 |

| Inter Clamp | 30mm L 40mm | Al6005-T5 | 100 |

| End Clamp | 30mm L40mm | Al6005-T5 | 100 |

| L Feet (Including Rubber, Bolts Andnut) | / | Extruded Aluminum & SUS 304 | 100 |

Integrated Solution 2

The Integrated Solution for Solar Mounting Aluminum Profiles is designed as a unified support system for photovoltaic installations. It includes precisely matched rails and clamps.

| PRODUCTS | SPECIFICATION | MATERIALS | QTY. (PCS) |

| Rail | 2500mm | Aluminum Alloy | 20 |

| Inter Clamp | 30mm L 40mm | Al6005-T5 | 100 |

| End Clamp | 30mm L40mm | Al6005-T5 | 100 |

Case Studies

FAQ Use & Operation

What Products Do You Manufacture?

We specialize in a wide range of aluminum profiles, including LED, solar mounting, architectural, general and industrial aluminum profiles. Our products are widely used in lighting systems, solar installations, building projects, furniture, automation equipment, and industrial structures.

What Is Your Manufacturing Capability?

We offer one-stop manufacturing, covering aluminum extrusion, CNC machining, cutting, drilling, surface finishing, assembly, and packaging. From raw aluminum billets to finished profiles, all processes are strictly controlled to ensure consistent quality and dimensional accuracy.

Do You Support OEM and Custom Aluminum Profiles?

Yes. OEM and ODM services are fully supported. We can develop custom aluminum profiles based on drawings, samples, or project requirements, including cross-section design, length, alloy selection, surface finish, and functional integration for specific applications.

How Do You Ensure Product Quality?

Quality is controlled throughout the entire process, from raw material inspection and in-process monitoring to final dimensional and surface checks. We follow standardized production procedures and conduct multiple inspections to ensure strength, straightness, surface consistency, and performance meet project expectations.

What Is The Typical Production And Delivery Time?

Production timelines vary by product type and order complexity. Standard profiles usually have shorter lead times, while custom aluminum profiles require additional time for tooling and sample approval. Once confirmed, we provide a clear production schedule to support reliable project planning.

Is There A Minimum Order Quantity?

MOQ depends on the profile type and customization level. Standard aluminum profiles generally require lower MOQs, while custom extrusion dies may involve a higher initial quantity. We aim to offer flexible solutions based on project scale and long-term cooperation.